Roof Leak Repairs in Milwaukee, WI 53295

Call our Roofing Leak Repairs line at 888-479-8303 for a prompt response to roof leaks and other roofing issues.

Our responsive team will dispatch a roofing contractor to your site within hours, depending on the severity of the roof damage, to quickly assess your residential or commercial roof and make necessary repairs on the spot.

When it involves putting the best touches on a home our roofing options can easily add curb appeal to any home. We can aid you make a expert roofing strategy to make sure that your home will be the very best it can be. The possibilities are endless when you call our Roofing professional Providers.

Continue Reading ...

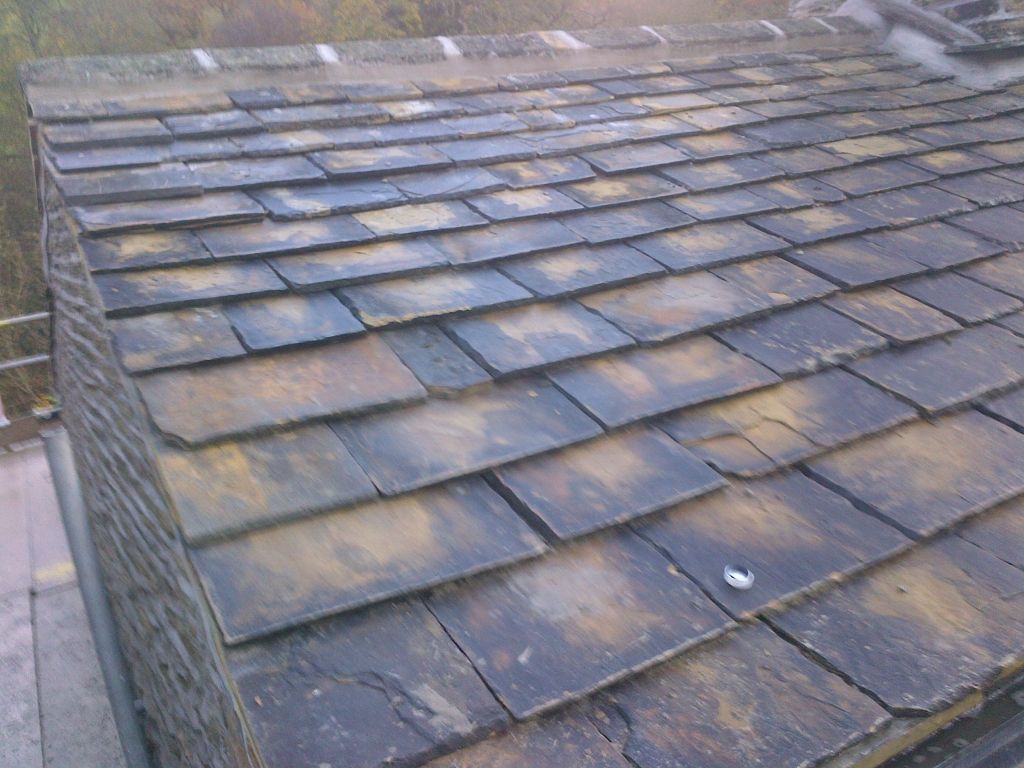

Traditional Roof

With all the roofing design and styles that you can select in the market today, you probably require a little aid to push you to the ideal instructions. Correct preparation and substantial time ought to be set aside in picking the perfect roof style that would best fit your home. Roofing systems considerably contribute to the appearance you want your house to depict.

considering timeless roof styles, you'll maybe discover the range almost limitless. From clay to metal tile, you can be specific that you can find the style that would best compliment your house. Classic roof typically requires a considerable quantity of workmanship and know-how. Adding roof information would greatly contribute to the charm and elegance of the roofing. That is why aside from choosing premium grade materials, it is equally crucial to employ just the very best roofer in your area. This would guarantee remarkable quality workmanship and your fulfillment.

Frequently, the use recycled roof materials are perfectly proper to help you in attaining the timeless roofing style to desire to pull off. It is also recommended to use the light-weight, artificial products if you like the conventional, timeless roof design.

standard roof products commonly used typically can not endure high winds and other severe weather condition elements as successfully as artificial materials. There are steel tiles which are created to look like traditional roof tile but with the benefit of much easier installation and considerably more affordable too. Synthetic roof materials are available in different styles and textures that you can choose from to attain the appearance you seek for your roofing. The artificial classic roofing will not only give you the protection and protection against harsh climate condition, you can confidently anticipate it to last longer than the basic cedar or slate roofs.

There are lots of newer slates and replica shakes that are in fact filled with rubber compounds, making it capable to better prevent the damaging UV rays, and more durable and fire resistant. Artificial materials are notably a lot easier to install using air pressured nail weapons.

first deciding the style of roof to wish to adjust, make sure to assess the benefits of every option. Decide which design that will best boost the charm of your home, and would still provide the durability that you require.

In thinking about traditional roof designs, you'll possibly find the variety nearly unlimited. Frequently, the usage recycled roofing materials are perfectly proper to help you in achieving the traditional roof design to desire to pull off. It is also advisable to use the lightweight, synthetic items if you like the traditional, timeless roofing design.

The synthetic traditional roof will not just give you the protection and protection against severe weather condition conditions, you can with confidence anticipate it to last longer than the basic cedar or slate roofs.

Roofing Leak Repairs near Milwaukee, WI

Our expert Leak Repair Roofers provide Roof Leak Repairs. If you have any questions or concerns about our service area, please give us a call today. We are competitively priced in this city from other roofing companies because we are confident that you will be thrilled with how your roofing project will turn out. Again, call today to schedule a estimate for your roofing job.

Leaking Roof Repairs in Milwaukee County

Ensuring you have Correct Roofing System Ventilation

Looking after your roofing system

A well cared for roof lasts much longer than a roofing system that is left to it's own devices. Your roofing system is responsible for taking the damage from everything that the components can throw at it including wind, rain, sun and snow however it is likewise attacked by leaves, pests and other natural predators.

Small problems cause huge problems.

leaks and damages is through a regular, professional upkeep check performed by an experience roofing professional in your place. These checks are not as costly as you may think and issues that location found early can be repaired before they worsen. One such problem that you need to regularly have actually examined is that you have appropriate roof ventilation and that it is working efficiently.

What is proper roofing ventilation?

a consumption or an exhaust, correct roof ventilation should comprise of both of these crucial aspects in order to produce impact air blood circulation in and out of your house. Not only will this secure your roofing and your house but it will likewise help control the quantity of time you use your a/c, thus bringing down the rate of your energy bills. There are a variety of ways that proper roofing ventilation can be achieved and each have their downsides and advantages. The best option for your roofing system will depend upon the size and shape of the roofing system, and the design of surrounding trees, wires and other items.

Producing correct roofing ventilation

produce proper roofing ventilation that sufficiently rotates air in and out of the house it is essential to get the level of consumption and expulsion ideal. This should be done by a qualified expert who can exercise the figures needed and encourage you of the best strategy. Without expert guidance you might discover that you have an incorrect flow of air, which can not only imply an extremely hot house in summer however it can likewise suggest a wetness develop in your loft and eventually warped, split, broken or typically damaged roofs.

Reasons for wetness buildup in the attic

It isn't constantly the fault of the weather either. Cleaning devices, clothes dryers and other home appliances along with the residents of your house all produce their own moisture and without appropriate roofing ventilation this wetness will develop on the inside of your roofing system. With an appropriate roofing ventilation system an unfavorable atmospheric pressure is produced that draws the warm air out of the loft changing it with cool fresh air from outside avoiding various types of damage associated with poor ventilation systems.

A well cared for roofing system lasts much longer than a roof that is left to it's own devices. Correct roof ventilation does not consist of either a consumption or an exhaust, proper roofing system ventilation ought to comprise of both of these crucial components in order to develop result air circulation in and out of your home. The finest choice for your roofing will depend on the size and shape of the roofing system, and the design of surrounding trees, wires and other things.

Washing makers, clothes dryers and other family appliances as well as the occupants of the house all create their own wetness and without correct roof ventilation this moisture will construct up on the inside of your roofing system.

Show Less

We at Stuart Roofer Services aim to produce the roof of your dreams! Call us today and set up a consultation with our specialist roofers. You won’t be dissatisfied. Call today for Roofing Services in Milwaukee!

We can provide Roof Leak Repairs for all areas in Milwaukee including: Milwaukee County, , Zablocki Va Medical Ctr and in Area Codes 414